Robotic arm project.আপনারা অনেকেই রোবটিক আর্ম তৈরি করতে চান ।এই পোষ্টের মাধ্যমে আমি সার্কিট ডায়াগ্রাম এবং কোডিং আপনাদের ভালোভাবে দেখিয়ে দেবো যাতে আপনারা এই প্রজেক্টটা খুব সহজেই করতে পারেন ।আমি ভিডিওতে বিস্তারিত দেখিয়েছি সার্কিট ডায়াগ্রাম এবং কোডিং তো এখানে আমি ছবি দিয়ে দিচ্ছি আপনারা এটা দেখে সহজে করতে পারবে না আশা করি ।

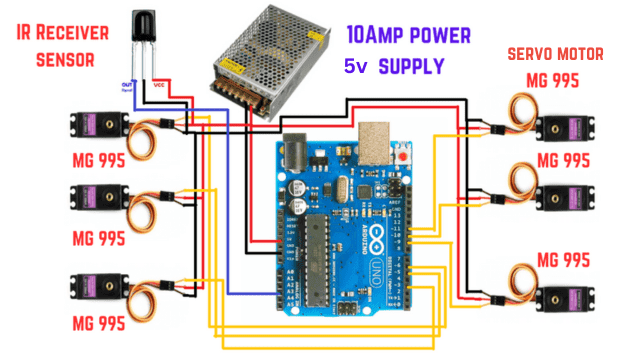

circuit diagram:

উপরের সার্কিট ডায়াগ্রাম অনুযায়ী কানেকশন করতে হবে ।আর আমি নিচে কোডিং টা ভালোভাবে দেখিয়ে দিচ্ছি ।যাতে আপনারা এটা নিয়ে খুব সহজেই প্রজেক্টটা করতে পারেন ।

components:

- Arduino Uno board

- Servo motors (6)

- Breadboard

- Jumper wires

- Power source (5V battery or power supply)

- remote

A robotic arm is a type of mechanical arm, usually programmable, with similar functions to a human component. The links of such a manipulator are connected by joints allowing either rotational motion (such as in an articulated robot) or translational (linear) displacement.

Robotic arms are used in various applications, including manufacturing, logistics, healthcare, and education. They are becoming increasingly sophisticated and versatile, and they are helping to automate tasks that humans once did.

Here are some of the critical components of a robotic arm:

- Base: The base is the arm’s foundation, providing stability.

- Joints: The joints allow the arm to move in different directions.

- Actuators: The actuators are the motors that power the joints.

- Sensors: The sensors provide feedback to the controller so that it can know where the arm is and what it is doing.

- Controller: The controller is the brain of the arm, and it tells the actuators what to do.

Robotic arms are a powerful tool that can be used to automate various tasks. They are becoming increasingly sophisticated and versatile, and they are helping to change the way we work.

Here are some of the benefits of using robotic arms:

- Increased productivity: Robotic arms can automate repetitive or dangerous tasks, which can free human workers to focus on more creative or strategic studies.

- Improved accuracy: Robotic arms can be programmed to perform high-precision tasks, reducing errors and improving product quality.

- Increased safety: Robotic arms can be used in hazardous environments, such as high temperatures or radiation.

- Cost savings: Robotic arms can save businesses money by automating tasks that human workers would otherwise do.

Best GPS Fleet Managment System 2023 : See NOW

#include <Servo.h>

#include <IRremote.h>

Servo servo1;

Servo servo2;

Servo servo3;

Servo servo4;

Servo servo5;

Servo servo6;

IRrecv IR(A3);

decode_results result;

#define M1 948321248

#define M2 948321232

#define M3 948321264

#define M4 948321224

#define M5 948321256

#define M6 948321240

#define M7 948321272

#define M8 948321220

#define M9 948321252

#define M10 948321266

#define M11 1910477319

int pos1 = 0;

int pos2 = 0;

int pos3 = 0;

int pos4 = 0;

int pos5 = 0;

int pos6 = 0;

void setup() {

Serial.begin(9600);

IR.enableIRIn();

servo1.attach(9);

servo2.attach(10);

servo3.attach(11);

servo4.attach(3);

servo5.attach(5);

servo6.attach(6);

}

void loop() {

if (IR.decode(&result)) {

Serial.println(result.value);

IR.resume();

}

delay(100);

if (result.value == M1 ) {

motor11();

delay(100);

// motor22();

// delay(100);

motor6();

delay(100);

motor5();

delay(100);

motor444();

delay(100);

//motor222();

//delay(100);

motor111();

delay(100);

motor44();

delay(100);

motor6();

delay(100);

}

if (result.value == M2) {

motor2();

}

if (result.value == M3) {

motor3();

}

if (result.value == M4) {

motor4();

}

if (result.value == M5) {

motor5();

}

if (result.value == M6) {

motor6();

}

if (result.value == M7) {

motor6();

}

if (result.value == M8) {

motor6();

}

if (result.value == M9) {

motor6();

}

if (result.value == M10) {

motorstop();

}

else if (result.value == M11) {

motorstop();

}

}

void motor1(){

for (pos1 = 0; pos1 <= 100; pos1 += 1) {

// in steps of 1 degree

servo1.write(pos1);

delay(100);

}

for (pos1 = 100; pos1 >= 0; pos1 -= 1) {

servo1.write(pos1);

delay(100);

}

}

void motor2(){

for (pos2 = 0; pos2 <= 30; pos2 += 1) {

// in steps of 1 degree

servo2.write(pos2);

delay(100);

}

for (pos2 = 30; pos2 >= 0; pos2 -= 1) {

servo2.write(pos2);

delay(100);

}

}

void motor3(){

for (pos3 = 0; pos3 <= 180; pos3 += 1) {

// in steps of 1 degree

servo3.write(pos3);

delay(15);

}

for (pos3 = 180; pos3 >= 0; pos3 -= 1) {

servo3.write(pos3);

delay(15);

}

}

void motor4(){

for (pos4 = 0; pos4 <= 180; pos4 += 1) {

// in steps of 1 degree

servo4.write(pos4);

delay(15);

}

for (pos4 = 180; pos4 >= 0; pos4 -= 1) {

servo4.write(pos4);

delay(15);

}

}

void motor5(){

for (pos5 = 0; pos5 <= 180; pos5 += 1) {

// in steps of 1 degree

servo5.write(pos5);

delay(15);

}

for (pos5 = 180; pos5 >= 0; pos5 -= 1) {

servo5.write(pos5);

delay(15);

}

}

void motor55(){

for (pos5 = 0; pos5 <= 180; pos5 += 1) {

// in steps of 1 degree

servo5.write(pos5);

delay(15);

}

}

void motor555(){

for (pos5 = 180; pos5 >= 0; pos5 -= 1) {

servo5.write(pos5);

delay(15);

}

}

void motor6(){

for (pos6 = 0; pos6 <= 180; pos6 += 1) {

// in steps of 1 degree

servo6.write(pos6);

delay(50);

}

for (pos6 = 180; pos6 >= 0; pos6 -= 1) {

servo6.write(pos6);

delay(50);

}

}

void motor66(){

for (pos6 = 0; pos6 <= 180; pos6 += 1) {

// in steps of 1 degree

servo6.write(pos6);

delay(15);

}

}

void motor666(){

for (pos6 = 180; pos6 >= 0; pos6 -= 1) {

servo6.write(pos6);

delay(15);

}

}

void motor11(){

for (pos1 = 0; pos1 <= 100; pos1 += 1) {

// in steps of 1 degree

servo1.write(pos1);

delay(100);

}

}

void motor111(){

for (pos1 = 100; pos1 >= 0; pos1 -= 1) {

servo1.write(pos1);

delay(100);

}

}

void motor22(){

for (pos2 = 0; pos2 <= 30; pos2 += 1) {

// in steps of 1 degree

servo2.write(pos2);

delay(100);

}

}

void motor222(){

for (pos2 = 30; pos2 >= 0; pos2 -= 1) {

servo2.write(pos2);

delay(100);

}

}

void motor33(){

for (pos3 = 0; pos3 <= 180; pos3 += 1) {

// in steps of 1 degree

servo3.write(pos3);

delay(15);

}

}

void motor333(){

for (pos3 = 180; pos3 >= 0; pos3 -= 1) {

servo3.write(pos3);

delay(15);

}

}

void motor44(){

for (pos4 = 0; pos4 <= 180; pos4 += 1) {

// in steps of 1 degree

servo4.write(pos4);

delay(15);

}

}

void motor444(){

for (pos4 = 180; pos4 >= 0; pos4 -= 1) {

servo4.write(pos4);

delay(15);

}

}

void motorstop(){

servo1.write(0);

delay(100);

// servo2.write(0);

//delay(100);

servo4.write(0);

delay(100);

servo5.write(0);

delay(100);

servo6.write(0);

delay(100);

}

উপরে আমি আপনাদের কোডিং টা দিয়ে দিলাম আর আপনারা আমার ভিডিওটা ভালোভাবে দেখবেন তাহলে বিস্তারিত বুঝতে পারবেন ।

ভিডিওটা এখান থেকে দেখুন: See NOW